Welcome to the debate between two giants of the 3D printing world: PLA Filament and ABS Filament! Whether you’re new to this world or a seasoned enthusiast, you’ve surely wondered which is the better choice for your projects.

In this article, we’ll explore the unique characteristics of each filament, PLA or ABS, their most common uses, and help you make the right choice for your 3D printing needs.

PLA Filament: most popular in the 3D printing world

PLA Filament, or polylactic acid, is a popular choice among 3D printing enthusiasts due to its ease of use and environmentally friendly nature. This material is primarily made from renewable resources such as corn starch or sugar cane, making it a more sustainable option compared to other filaments.

Among the applications offered by this filament we find:

- Decorative figures.

- Toys.

- Architectural models.

- Art and jewelry pieces.

Main characteristics of PLA

- Biodegradable and environmentally friendly: PLA decomposes naturally, making it an ideal choice for those concerned about reducing their carbon footprint.

- Easy to print: PLA has a lower printing temperature compared to other filaments, typically between 190°C and 230°C, making it easier for beginners to work with. The bed temperature ranges from 50°C – 70°C and a printing speed of 50 – 90 mm/s is recommended. In addition, it is compatible with 99% of FDM printers on the market.

- Ideal for non-functional or decorative parts: due to its more fragile nature compared to other filaments, PLA is perfect for creating models and decorative parts that will not be exposed to intensive use.

ABS filament: stiffness and strength

ABS filament, or acrylonitrile butadiene styrene, is known for its strength and durability. Although it is not as environmentally friendly as PLA, it is a popular choice for those looking for stronger, more durable parts.

Among its applications we can highlight:

- Electronic device housings.

- Automotive parts.

- Tooling.

- Functional prototypes.

Main characteristics of ABS

- Higher mechanical and thermal resistance: ABS is stronger and more durable than PLA, making it ideal for applications requiring high impact resistance, stiffness and toughness.

- More prone to deformation: ABS has a higher thermal shrinkage during the printing process, which can lead to deformation of the printed parts if not properly controlled. In fact, a closed chamber is recommended.

The printing temperature is around 230 – 260ºC and the bed temperature is around 70 – 120ºC.

- Emits odors during printing: ABS can produce unpleasant odors during the printing process, so it is recommended to use it in a well-ventilated area.

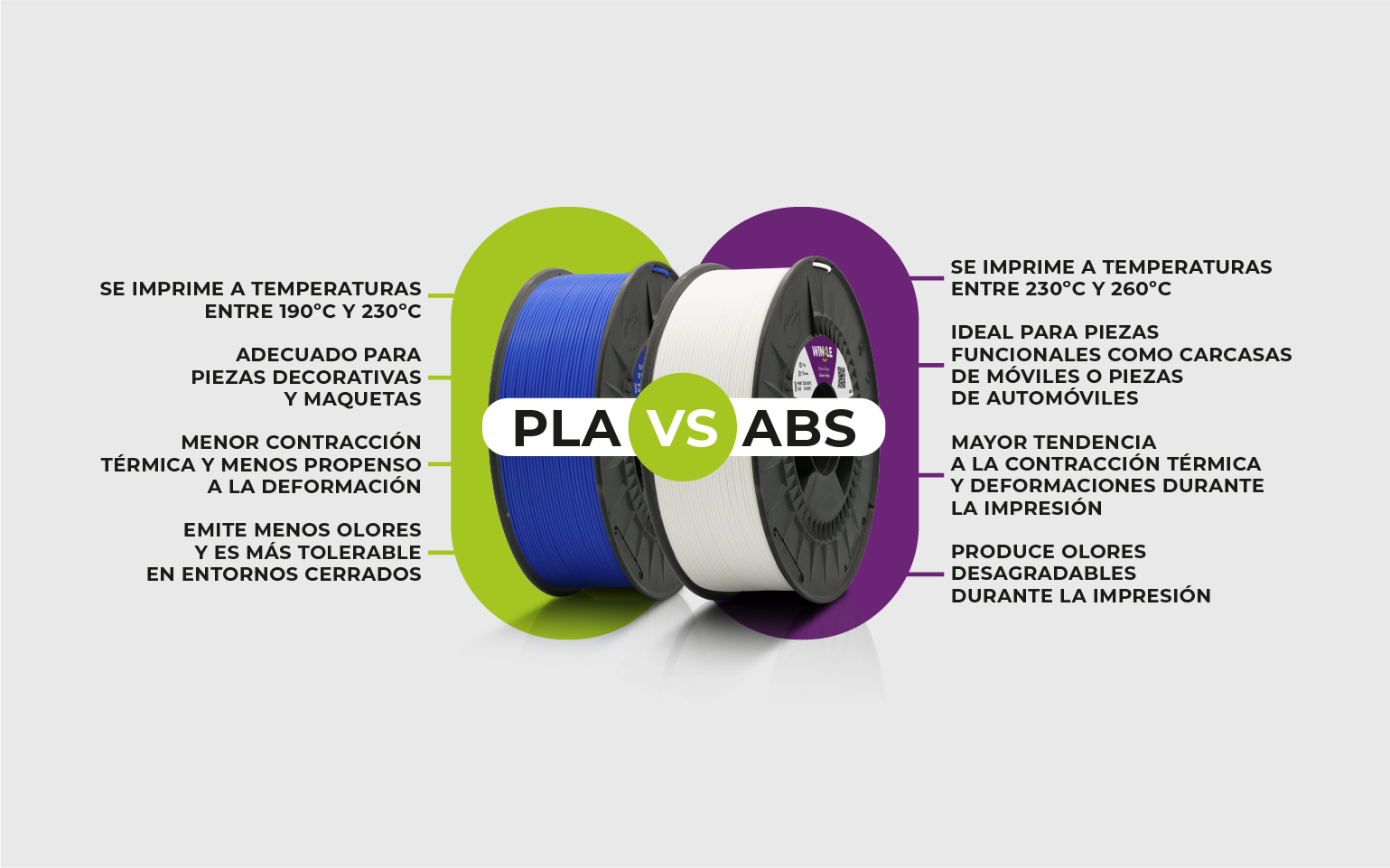

PLA vs ABS

Now that we have explored the individual characteristics of each filament, it is time to compare them directly:

Printing temperature:

- PLA prints at temperatures between 190°C and 230°C.

- ABS requires higher temperatures, generally between 230°C and 260°C.

This difference can significantly influence the type of printers you can use and the quality of the printed parts. For example, if you are using a printer with limited heating capacity, it may be necessary to work with PLA due to its lower printing temperatures.

Mechanical resistance:

- PLA is more suitable for parts that will not be subject to intensive use, such as decorative figures or models.

- ABS is ideal for parts that require greater resistance to impact, durability and high temperatures; such as electronic device housings or automotive parts.

For example, if you are printing a case for an electronic device that will need to withstand drops and bumps, you will likely choose ABS for its greater mechanical strength.

Deformation during printing:

- ABS has a greater tendency to thermal shrinkage during the printing process, which can lead to warping of printed parts if not properly controlled.

- PLA has less thermal shrinkage and is less prone to warping during printing.

For example, if you are printing a precision part that requires exact dimensions, you may prefer to work with PLA to avoid unwanted deformations.

Odors during printing:

- ABS tends to produce unpleasant odors during printing.

- PLA emits less odors and is more tolerable in closed environments.

This is especially important if you are printing in a shared workspace or indoors. For example, if you are printing in a poorly ventilated room, you may prefer to use PLA to minimize unpleasant odors.

Applications and practical uses:

- PLA is ideal for creating decorative and non-functional parts, such as figurines and art objects. For example, you can print a detailed miniature of a historical building or an abstract sculpture to decorate your home or office.

- ABS is perfect for functional parts that require strength and durability. For example, you can print a sturdy case to protect your cell phone or a tool holder that needs to withstand heavy use.

Conclusions PLA vs ABS

In conclusion, both PLA and ABS filament have their own advantages and disadvantages, and the choice between them will ultimately depend on the specific needs of your project. If you are looking for a more eco-friendly and user-friendly option, PLA may be the best choice for you.

On the other hand, if you need stronger, more durable parts, ABS might be the better choice.

Ultimately, there is no “best” filament, but rather a filament that is right for each situation. Experiment with both and find out which one works best for your 3D printing projects.

Which one do you use?